Paving Michigan with Quality, Sustainable Roadways

- M. Emin Kutay, Ph.D., P.E.

- Assistant Professor

- Department of Civil and Environmental Engineering

Sometimes dubbed "pot-hole season," winter can be hard on Michigan's roadways, as well as costly, in terms of both dollars and environmental impact.

Seeking a quality, sustainable and cost-effective solution to this problem, Dr. M. Emin Kutay, of MSU's Department of Civil and Environmental Engineering, has been working on a collaborative project to develop guidelines for increasing the use of crumb rubber in asphalt pavements constructed in Michigan. The project is sponsored by MSU, the Michigan Department of Environmental Quality (MDEQ), and the Ingham County Department of Transportation and Roads.

Obtained from scrap tires destined for landfills, crumb rubber is repurposed for use in modified asphalt mixes. The crumb rubber is supplied by a Michigan company that grinds up the old tires and distributes the crumb rubber throughout the country. According to Kutay, in a four-lane asphalt roadway the number of tires used ranges from 2,000 to 8,000 per mile, resulting in a substantial savings in landfill space.

Kutay became interested in pavement issues as a graduate research fellow working on his doctorate in civil and environmental engineering at the University of Maryland, College Park. During that time, he had the opportunity to work at the Turner Fairbank Highway Research Center (TFHRC), a state-of-the-art facility owned and operated by the Federal Highway Administration. "At TFHRC, there were numerous interesting research projects I was able to get involved in," he said. "Specifically, applications of X-ray computed tomography to study internal structure characteristics of asphalt pavements piqued my interest." One project involved the successful use of crumb rubber technologies in combination with local Virginia aggregates (i.e., gravel components) to produce superior paved surfaces.

With positive outcomes from the project in TFHRC located in McLean, VA, Kutay was interested in seeing if the technology would be compatible with and applicable to local mid-Michigan aggregates. So, with a grant from the MDEQ, Kutay and his fellow researchers at MSU's Advanced Asphalt Characterization Laboratory (AACL), an American Association of State Highway and Transportation Officials accredited laboratory, conducted extensive research on potential mix designs.

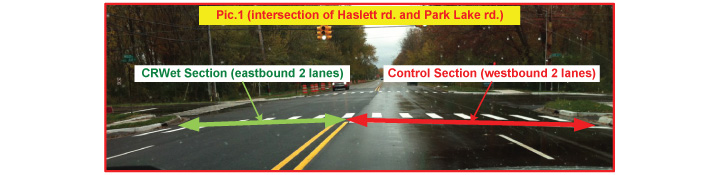

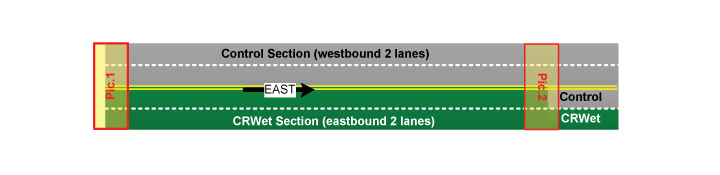

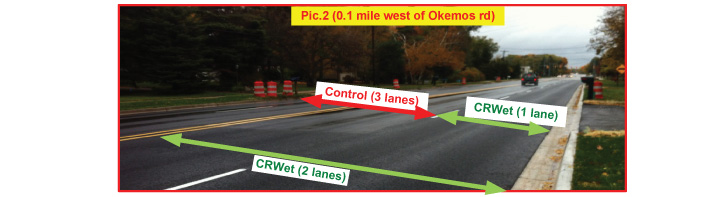

"The AACL researchers conducted performance tests in the laboratory and identified several candidate mix designs that are expected to perform well in the field," said Kutay. "Then these designs were used to develop crumb rubber modified asphalt specifications." The two specifications for crumb rubber modifications they developed—the Crumb Rubber Terminal Blend (CRTB) and the Crumb Rubber Wet Process (CRWet)—were tested in two Ingham County test sites—on Waverly Road, using the CRTB blend, and on Haslett Road, using the CRWet blend.

Kutay has been working in partnership with the Ingham County Department of Transportation and Roads (ICDTR), which designed and constructed the two field test sections and provided technical feedback related to developing contract specifications for the mixtures. According to Daniel Troia, P.E., project engineer at the ICDTR, one of the challenges in this kind of project is translating laboratory research into construction specifications that take into account "real world" production tolerances inherent when using natural materials such as sand and gravel.

While current industry standards involve the addition of expensive polymers to improve the quality of asphalt, the hope is that the crumb rubber (CR) modified HMA mixtures will outperform polymer modified mixtures in Michigan traffic and weather environments, at equal or less cost.

Initial testing at the Ingham County field test sites has been encouraging, but it will be some time before the performance of the mixtures at these sites can be assessed. "The real benefits won't be apparent until the unmodified mixture starts to reach the later stages of its life cycle at 15 to 20 years," said Troia. "This is the time when we anticipate that the beneficial chemicals in the CR will act to deter or delay the environmental degradation that the unmodified mixture will undergo."

When Kutay presented the initial test site results to MSU's physical plant administration, they agreed to replace a section of paved road on the MSU campus with the CRTB mixture. In August 2012, they constructed a section of Chestnut Road using the CRTB technology.

Although current funding will end on December 31, 2012, Kutay's team has already been awarded another MDEQ grant for the purpose of expanding his research to investigate crumb rubber mixes appropriate for sidewalks and trails. The Physical Plant administration will construct the Riverwalk Trail (next to the Red Cedar River) with the new mixture. "We are hoping to increase the crumb rubber usage in the asphalt mixture significantly," said Kutay.

Besides decreasing the number of tires in landfills and increasing resistance to cracking and rutting, there are other benefits to using crumb rubber in asphalt. The CRM mixtures have been shown to improve skid resistance, decrease pavement noise, and slow the aging (oxidation) process of the road, due to anti-oxidants already present in scrap tire rubber. According to Kutay, "this significantly reduces the maintenance costs and increases pavement life." He is excited about the work: "This is a sustainable method of asphalt mixture construction. It has great environmental benefits. In addition, the technology allows us to construct better roads."

- Written by Amy Byle, University Outreach and Engagement

- Photographs courtesy of M. Emin Kutay, College of Engineering